Turnkey Test Systems

Up your test game with a Turnkey Test System from Wired-in Software

At Wired-in Software, we build custom Automated Test Equipment in Melbourne, Australia. Our test systems help our customers reduce errors, free up resources and gain insights.

Who is our Turnkey Test Systems for?

We build Turnkey test systems for:

- Production Engineers/Managers

- Product Designers

- Quality Assurance and

- Test Engineers

Problems we solve:

- Obsolescence, due to non-COTS hardware

- Poor documentation, done in in house and rushed to get completed

- Unreliable equipment, due to not choosing hardware fit for purpose

- Difficult to maintain test software, by not using a standardised platform for testing

- Human error and poor test coverage, as a result of manual testing

- Internal engineers not focusing on the product design, resulting in blown out timelines

- Slow time to gain test insights, due to manual data collection process

What is Automated Test Equipment?

Turnkey test systems can be called many things. Other names include Automated Test Equipment (ATE), Test System, Production Tester, PCB Test System, End Of Line (EOL) Tester and more.

A test system is a custom-built system that typically resides in a manufacturing or R&D environment, and automatically tests the product to ensure it is designed and/or built to a clearly defined set of requirements.

Types of test systems

There are a variety of turnkey testing system types:

- 1. Flying Probe Tester - Generic test equipment that is programmed to check the static values of each PCBA component. No functional testing is included. Wired-in Software does not develop these.

- 2. In circuit tester (ICT) - Passive PCBA checking. Wired-in Software does not do these.

- 3. Functional Circuit Tester (FCT) - Also known as PCB tester, or electronic functional tester. Can often be a hybrid between ICT and functional, but each product under test will inevitably be powered up, programmed, and functionally verified.

- 4. QA check tester - Test equipment for warranty returns and repairs. Typically built to the same specification as the FCT.

- 5. Hardware in the loop (HIL) tester - These test systems are built for R&D departments and product design teams responsible for product V&V, and focuses on validating the product design, durability, device characterisation, and often requires modelling the system.

Ways in which we can help - Our Test System Offerings

Turnkey Test Systems

This is our core offering. This is for customers who have no experience with building test equipment, and are looking to outsource the entire project.

We will run the entire project, including requirements and design, electrical, electronic industrial design and build, and instrumentation selection, and development of the test software.

Click below to see some of our work.

Test System Software

Quite often, our customers are capable of building the test hardware, but just need support with developing the test software.

This is where we shine.

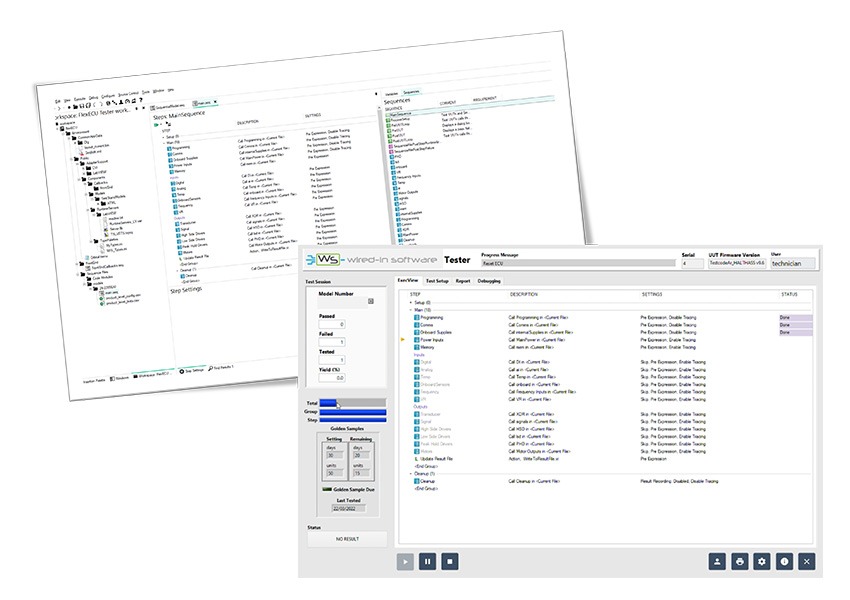

We use NI Systemlink, NI TestStand, NI LabVIEW, and Bloomy EFT Module, as well as the Wired-in Software TestStand Templates.

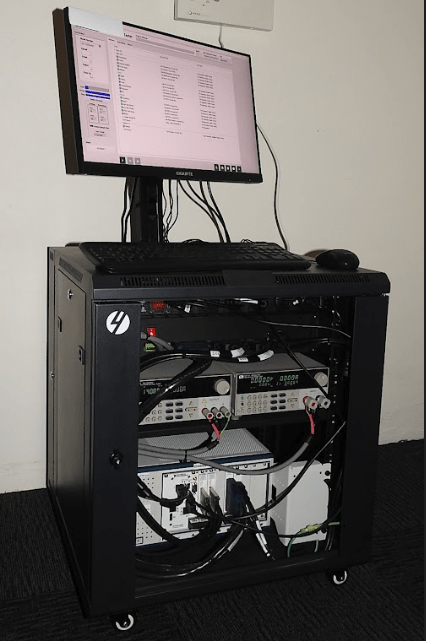

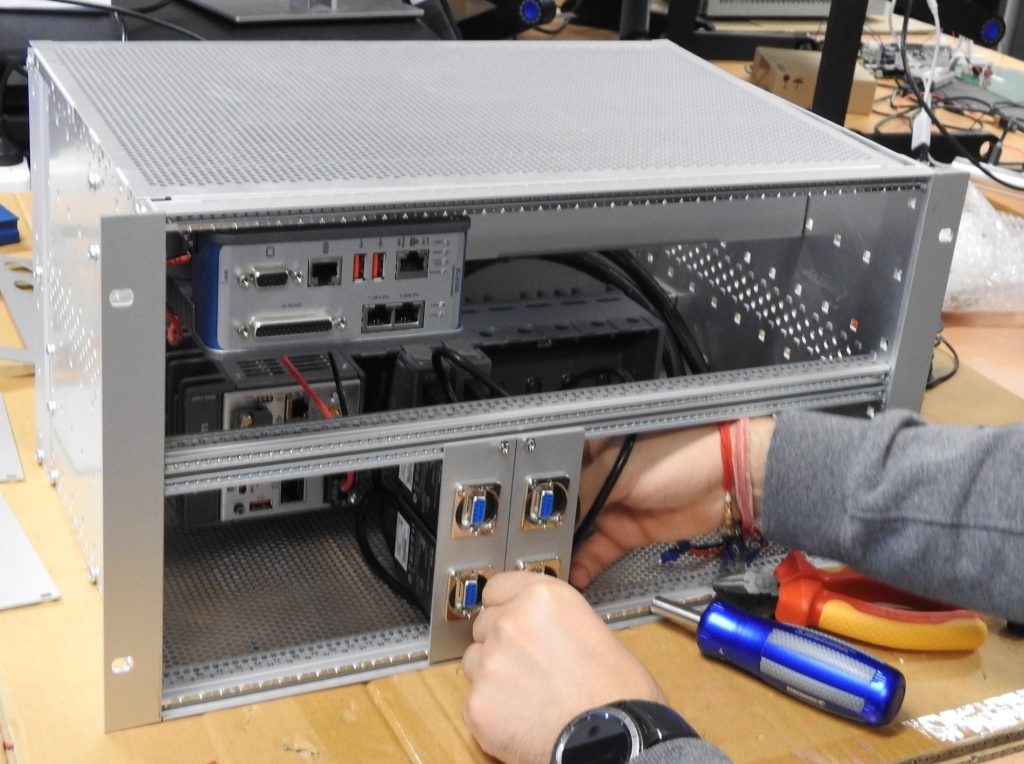

Custom Rack Design and Build

Wired-in Software can design and build a custom rack layout to suit your testing requirements.

Our service includes electrical, electronic and industrial design.

Our racks meet Australian electrical standards.

We build the racks at our office, and leverage local machine workshops to carry out precision manufacture.

Test System Support and Maintenance

Once our test system is deployed, we have a number of support packages we offer to ensure production uptime stays high.

Click on the button below to learn more about the support packages below.

What do you get with a typical Wired-in Software Turnkey Test System?

Features

-

Minimal Custom Hardware

We focus on designing a COTS based system to fast track delivery, therefore minimal custom hardware design.

-

Semco Test Fixtures

Made in USA, rugged, and various sizes and interface options.

-

NI PXI Hardware

NI PXI hardware is compact, large range of interfaces and switching options, high performance. We start here, but can accommodate a variety of NI and 3rd party instruments as required.

-

NI LabVIEW+ Software

NI LabVIEW+ includes LabVIEW, TestStand, and more. TestStand can call test code from multiple sources, whether it be LabVIEW, .NET, Python and more.

-

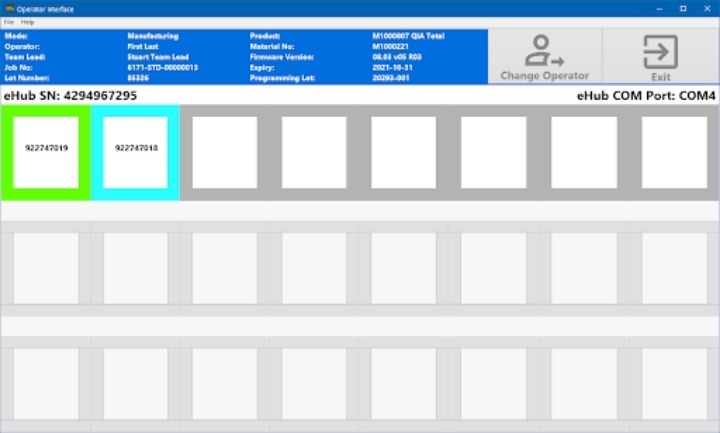

Bloomy EFT Module for TestStand

Includes an out of the box Operator Interface for TestStand, the Hardware Access Framework (HAF), and SQL reporting.

-

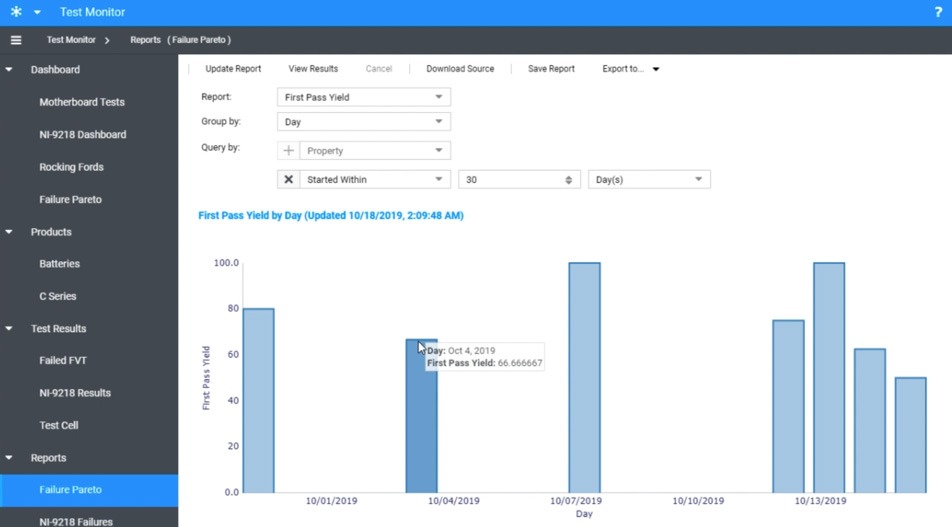

NI Systemlink for Data Management

NI Systemlink is a cloud (or on-prem) application to manage multiple test systems and locations, asset management, test data storage, and insights

-

Wired-in TestStand Template

Setup and ready to run

-

Post Delivery Support

Each test system comes with a basic warranty for 3 months. Standard or Premium support package upgrade options are available.

Benefits

-

Frees up Internal Resources

Our focus on an automated test solution that is built well, frees up your design and maintenance engineers. They stay focussed, timelines don't slip, and production uptime stays high.

-

Faster time to market

By using COTS hardware, and starting with our software stack, and minimising the custom hardware design required, you can get up and running fast.

-

Low Test Code

Using the Bloomy EFT Module for TestStand, and combining it with NI LabVIEW+ and Wired-in Software's TestStand template, less code is required to get the test system framework in place. The Bloomy EFT Module supports a large set of devices out of the box. This means you can concentrate on developing your test sequence sooner.

-

Real-time Test Insights

With NI TestStand easily connected to NI Systemlink, you can get test data insights as it happens. With the dashboard feature, you can provide critical data to the production floor. On the backend, QA can be analysing the test results and performing out-of-the-box SPC analysis such as Pareto.

-

Standardised Platform

Using NI hardware, software, and data management tools, ensures you have a standardised approach to building test equipment. With 800+ NI Alliance Partners globally, you are guaranteed the software will be supported for it's entire lifetime.

-

Trusted Test Partner

Build a trusted partnership that is sustainable and lasts the distance. Ensures longevity, reliability, and one less thing keeping you awake at night.

How We Build Automated Test Equipment

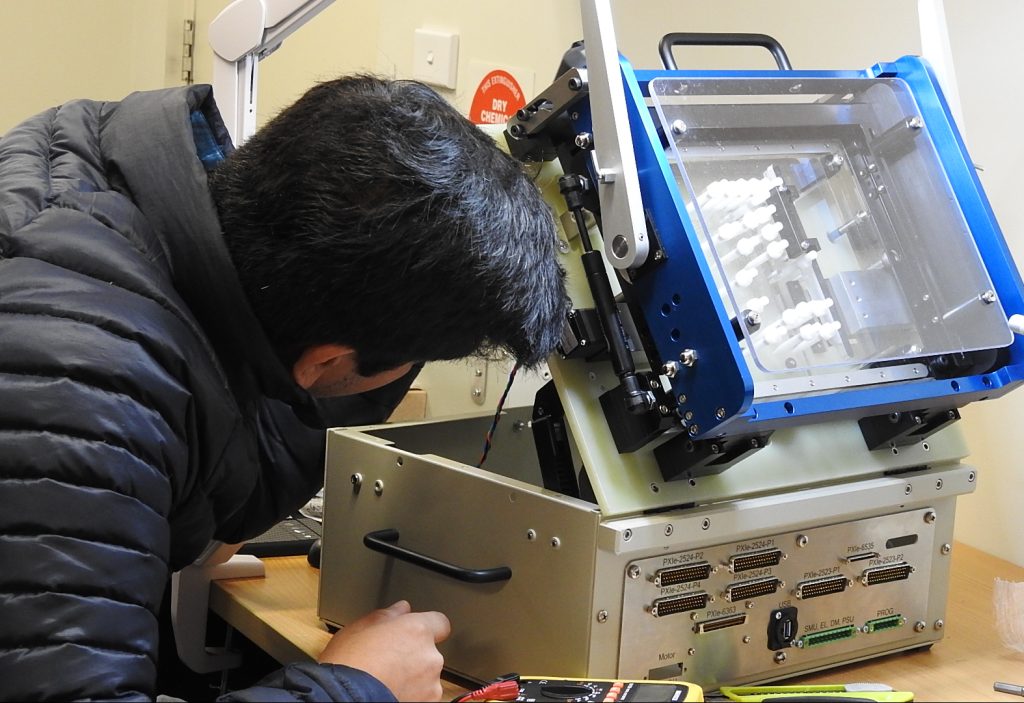

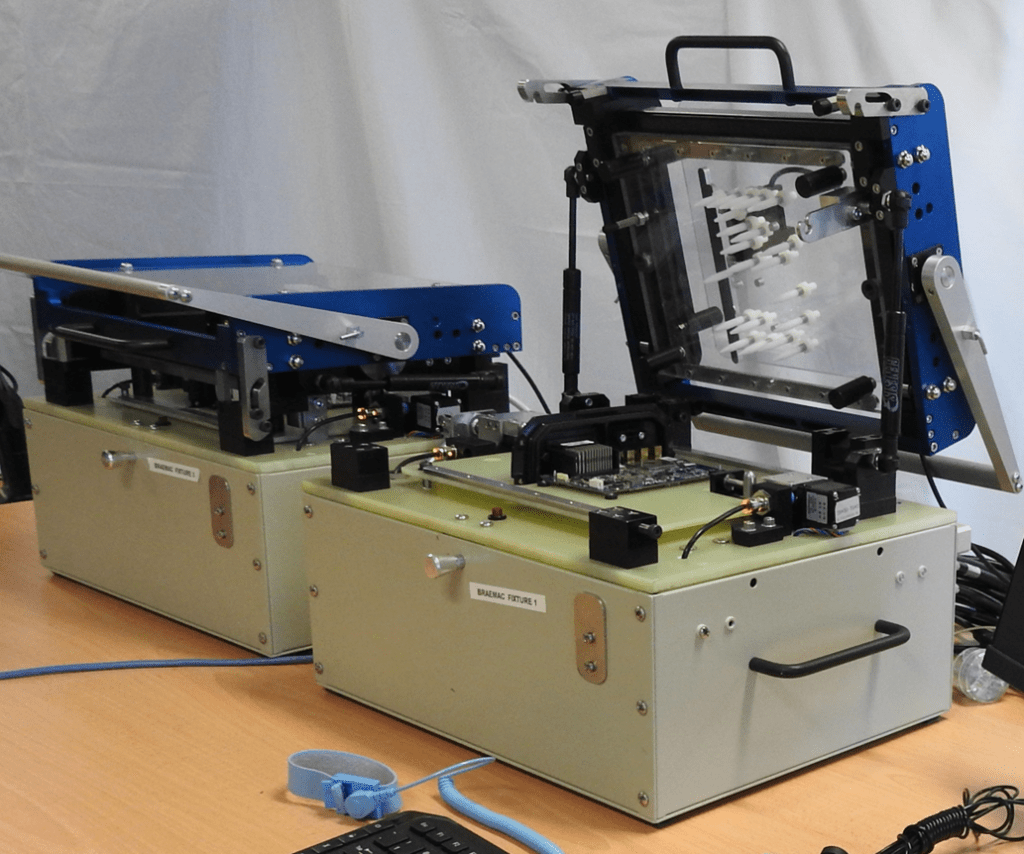

Automated Test Equipment - fixtures

The test fixture is where the device under test (DUT) is connected to the test system. This typically takes the form of a bed of nails, but can also be simply through the DUT external connectors.

Our test fixtures and kits are based on the Semco Camgate test kits. We customise these for each customer.

Customisations include:

- Barcode scanner mounting

- Test pin locations

- Manual connections

- Solenoids and interlocks

- Custom interface PCBA

- Custom interconnect panels

Custom Electronics Interfacing

Some test application require a custom electronic module to interface between the Unit Under Test (UUT) and the instrumentation. A custom solution can save space and maintain signal integrity

This includes:

- Test pin to instrument signal routing

- Resistive loads

- Custom connectors

- Power distribution

- Signal conditioning

- Switching / relays / multiplexing

- Sensor inputs

Automated Test Equipment - Instrumentation

- Large range of switching options to reduce custom interface electronics

- Robust and compact packaging, for longer life and replaceability

- High performance, and high channel counts

- A range of calibration options

- Tight synchronisation and timing

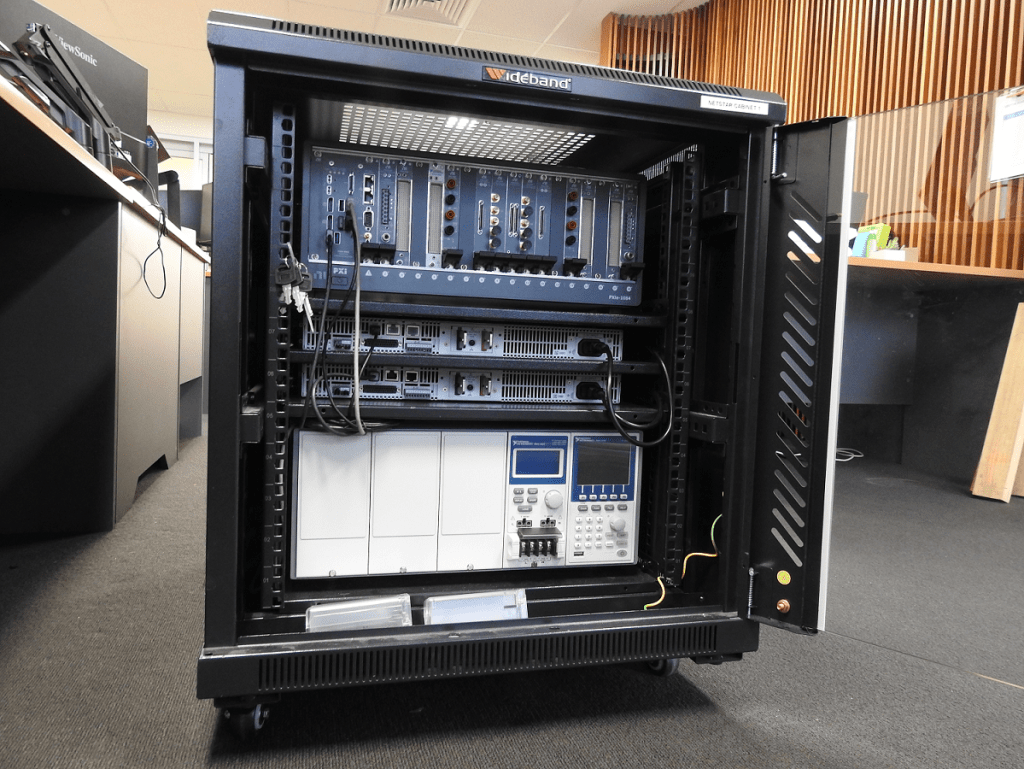

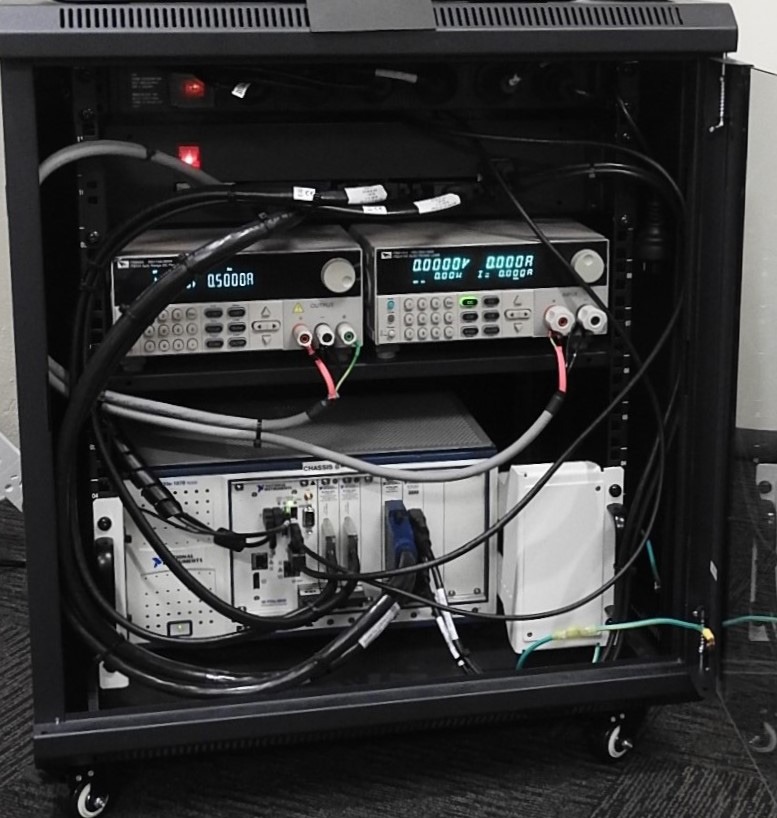

Cabinets and Cabling

Our Automated Test Equipment built in Melbourne typically house the instrumentation in a 19″ cabinet.

This includes:

- Power supplies

- Programmable Electronic loads

- PXI chassis and modules (ie. Embedded controller, Switches, DMM, Multi-function DAQ, SMU, I2C/SPI interface, etc)

- Custom and off-the-shelf cabling connecting from the fixture to the instruments

- Power board and cooling fans

- Shelves and cable inlets

- Wheels

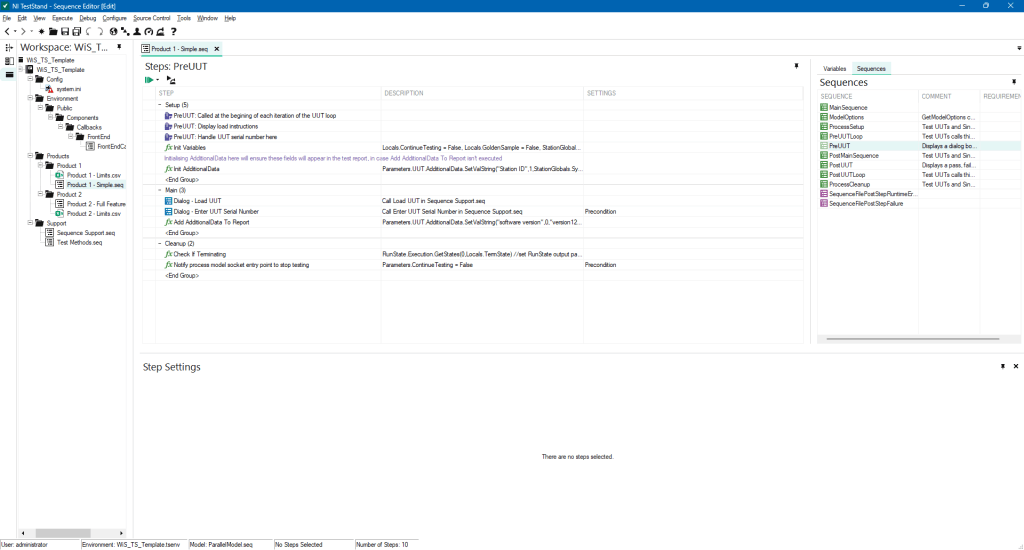

How We Develop Automated Test Software

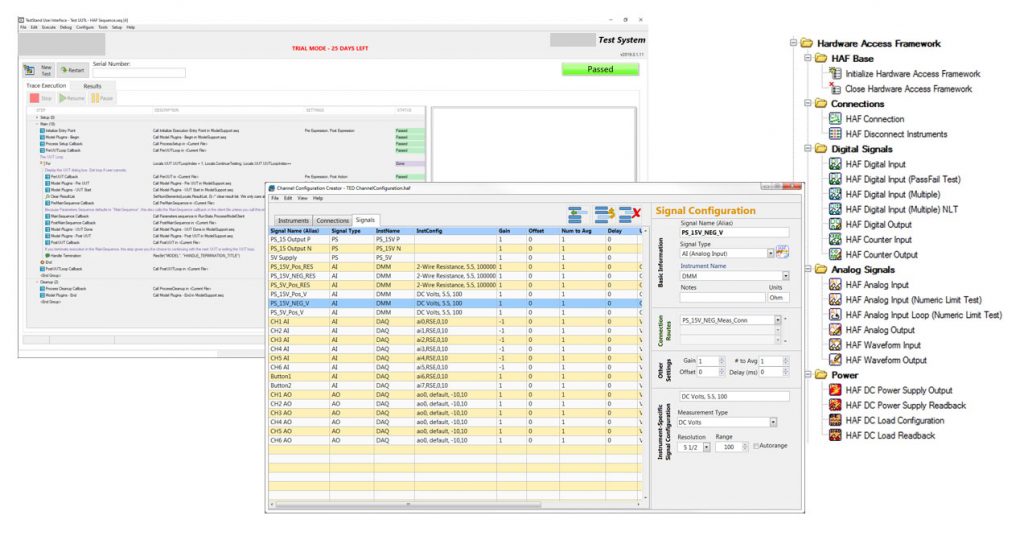

NI TestStand and LabVIEW

- NI TestStand is a standard test execution and management tool

- NI TestStand can interface with LabVIEW, Python, C, and more

- NI TestStand is highly extensible, and be customised to suit various situations

- NI TestStand has a parallel process module for allowing test of multiple DUTs at once

NI Systemlink

NI Systemlink is an enterprise level cloud-based application for managing your test configuration and assets, collating test results and data, and performing test analysis to gather insights.

Wired-in Software uses it internally for our own testing/validation of the systems that we build for our customers, and it’s great for insights and real-time test data.

Bloomy EFT Module for TestStand

Wired-in uses the Bloomy EFT Module for TestStand, to help simplify our test system development.

The EFT Module for TestStand includes three handy add-ons for TestStand:

- The Hardware Access Framework - a tool to configure the instruments/signals/channels of the test system, and integrate this easiily into TestStand via intuitive step types.

- SQL Database Viewer - A great starting point for collecting and reviewing TestStand test result data.

- Operator Interface - An advanced operator interface for production environments, with intuitive displays and setup.

Wired-in Software TestStand Template

We have developed a template for TestStand to get us up and running quickly.

The template includes a custom OI, process model callbacks, front end callbacks, configuration import/export, device driver templates and more.

How To Start

Need someone to help with Automated Test Equipment in Melbourne, Australia, or beyond?

Contact us for a free, no obligation planning discussion to work out the best path forward for your test and measurement challenge.

In addition, we recommend reading about our up-front design service, to learn whether your organisation would benefit from this before we jump into development.