Wired-in uses simulation electronics for a control system to overcome lockdown

Wired-in Software developed control system simulation electronics to help overcome COVID-19 lockdown restrictions.

Project Background

A wind tunnel control system for research purposes needed to be developed based on a cRIO controller working as a slave controller. This was to run in conjunction with a Windows PC acting as a master controller.

This system was to be able to provide open loop or closed loop control based on either air speed, Reynolds number, or fan motor speed. The system was to also allow logging of system states to file and then downloading the log files to the Windows PC during test runs.

The system needed to be developed from scratch in four months during a COVID-19 lockdown period without any access to the wind tunnel system itself.

The solution: Control system simulation electronics

Kim Bentley from Wired-in Software worked off-site to undertake the detailed system design and documented this in a design specification that was approved by the client. Then implementation of the system proceeded off-site.

Fortunately, Wired-in Software (a NI Alliance Partner and DQMH(R) Trusted Advisor) was able to greatly speed up the development of the system by utilising the LabVIEW-based DQMH toolkit from USA-based company, Delacor.

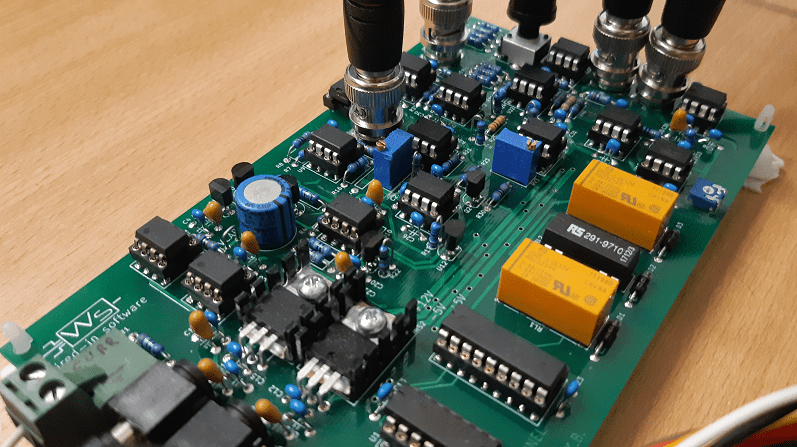

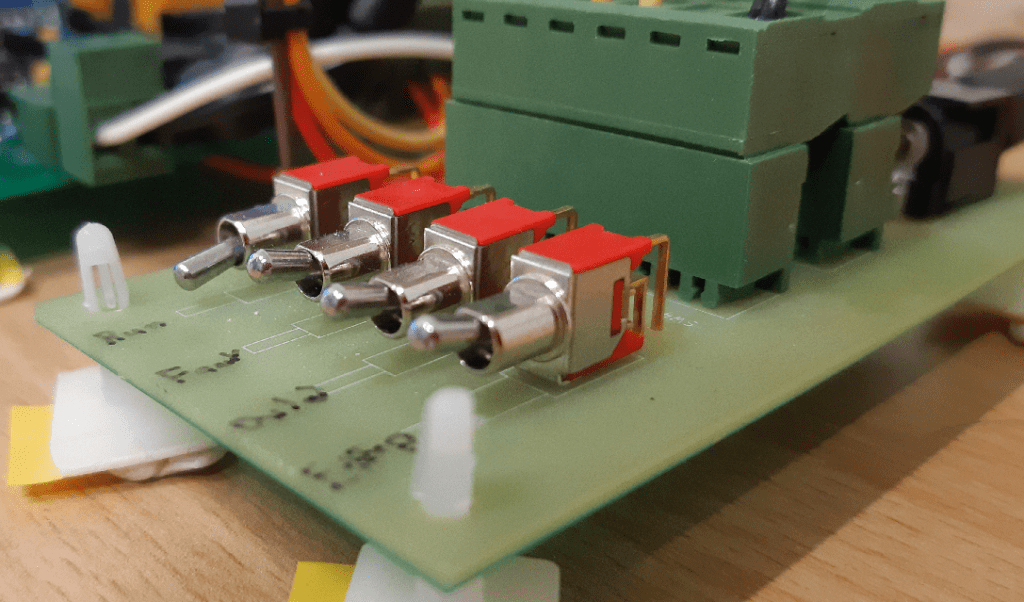

Given that the actual wind tunnel system was unavailable during software development, Kim spent three weeks to design, build, and commission custom control system simulation electronics. This then connected to the cRIO controller and simulated the entire wind tunnel system.

This approach allowed the control system software to be fully developed and tested to maturity in three months, offsite from the wind tunnel facility. The client was then able to meet with Kim at Wired-in’s premises to inspect and ‘sign-off’ the fully integrated work prior to on-site commissioning.

Streamlined Commissioning

Eventually, COVID-19 restrictions relaxed. Kim was then able to work on-site (with the client present at all times) to undertake the final software installation and commissioning phase. This work took four days to complete.

The client was extremely pleased with Wired-in Software’s working relationship throughout the project. Of particular note, they praised the short installation and commissioning phase and the excellent final results. This included being an intuitive system having outstanding performance, readily extendable, and with solid reliability – all backed up by Wired-in Software’s delivered product support.

Had the wind tunnel control system simulation electronics not been developed and used for software development, the installation and commissioning phase would have needed at least four weeks of software development prior to installation and commission the system. This would have meant that the system would have been finished four weeks later, the client would have been greatly inconvenienced, and the wind tunnel facility unusable for that additional timeframe.

About Wired-in Software

Wired-in Software are located in Melbourne (Australia), and an NI Alliance Partner that specialises in LabVIEW-based automated test and measurement applications, including systems that can do machine vision, monitoring and control, and embedded products. We are focused on helping our customers transition to be Industry 4.0 ready, by building intelligence into our applications. For more information, feel free to contact us for a no-obligation chat, or continue to peruse our website to learn more.